Non woven lining and woven lining: a guide to fabric selection¡¡Published by£º2025-03-14¡¡¡¡Categories:Industry news¡¡Viewed by: 1834 times Non woven lining and woven lining are two commonly used lining fabrics in clothing production. Non woven lining (paper lining) and woven lining (cloth lining) are two common types of lining materials, each with its own characteristics and suitable for different production needs. The following is a comparative analysis and selection guide for two types of lining fabrics to help you make a reasonable choice based on your needs:  1. Non woven interlining

characteristic:

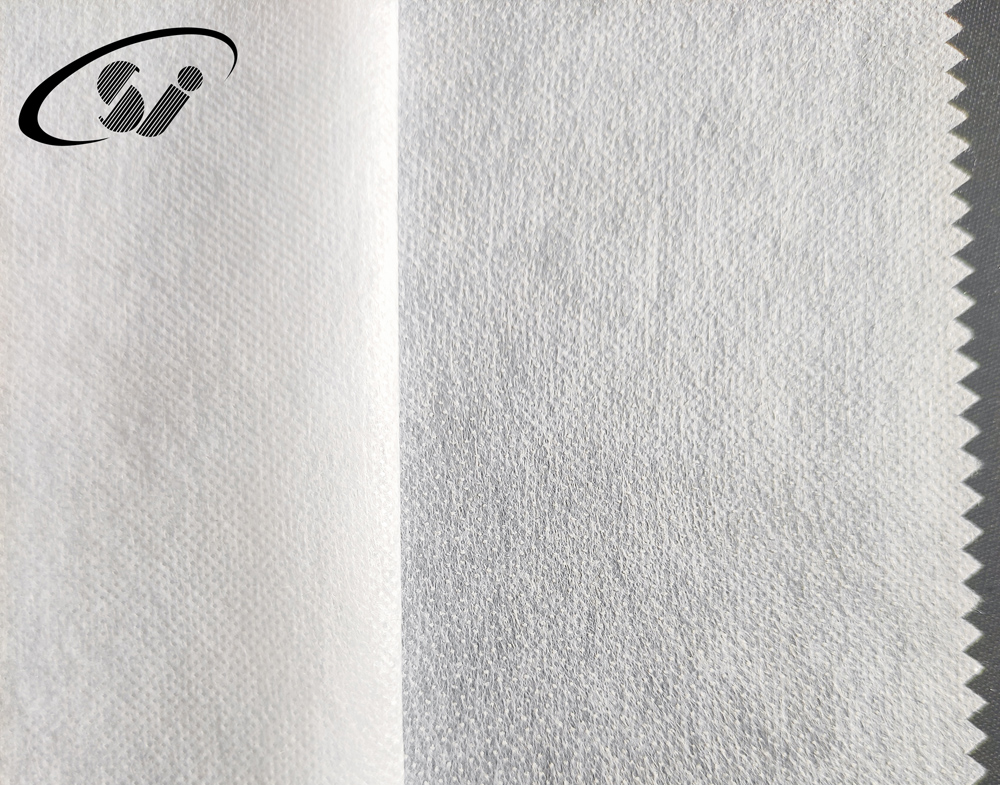

-Material: Made of polyester, nylon, or viscose fibers through chemical or thermal bonding, without interwoven warp and weft yarns.

-Structure: Uniform texture, no texture on the surface, soft to the touch.

-Features: Lightweight, breathable, low price, but low strength, poor washing resistance, and easy shrinkage and deformation at high temperatures.

Applicable scenarios:

-Lightweight fabrics: such as chiffon, silk, thin cotton, etc., used for areas that require lightweight support (such as collars and cuffs).

-Temporary styling: suitable for clothes that do not require frequent washing or decorative purposes (such as manual DIY, cloth embroidery).

-Low cost project: clothing with limited budget or disposable use.

matters needing attention:

-Avoid high-temperature ironing (low temperature+steam is recommended).

-Not suitable for heavy fabrics or areas that require high strength (such as suit shoulders).

2. Woven Interlining

characteristic:

-Material: Woven from cotton, polyester cotton, or synthetic warp and weft yarns, similar to ordinary fabrics.

-Structure: Weaving texture with warp and weft yarns, resulting in a tighter texture.

-Characteristics: High strength, washable, high temperature resistant, good shaping effect, but relatively thick, slightly poor breathability.

Applicable scenarios:

-Thick or elastic fabrics: such as woolen, denim, and knitted fabrics, used for areas that require strong support (such as the front of a suit or the collar of a coat).

-High demand clothing: formal attire, outerwear, bags, and other items that require long-lasting styling.

-High temperature processing: can withstand high temperature ironing, suitable for occasions that require pressing or bonding processes.

matters needing attention:

-Pay attention to the thickness matching between the lining and the fabric to avoid stiffness.

-The price is higher, but the durability is better.

**General recommendations**

-* * Testing priority * *: Cut a sample before use to test the bonding effect, shrinkage rate, and hand feel between the lining fabric and the fabric.

-Elastic Matching: Elastic fabric should be paired with elastic lining (such as woven lining for knitting) to avoid restricting movement.

-* * Environmental considerations * *: Non woven liners are mostly made of synthetic fibers, while spun liners can choose natural fibers (such as cotton liners) for greater environmental protection.

-* * Composite use * *: Complex clothing can mix two types of lining fabrics locally (such as non-woven lining for light and thin parts, and woven lining for stressed parts). |

|

Contact:YU Qinxian Tel:+86-13587903622 E-mail£ºcathy@sanjininterlining.com Fax£º+86-0572-6603299 |